Mig Welding Weave Patterns

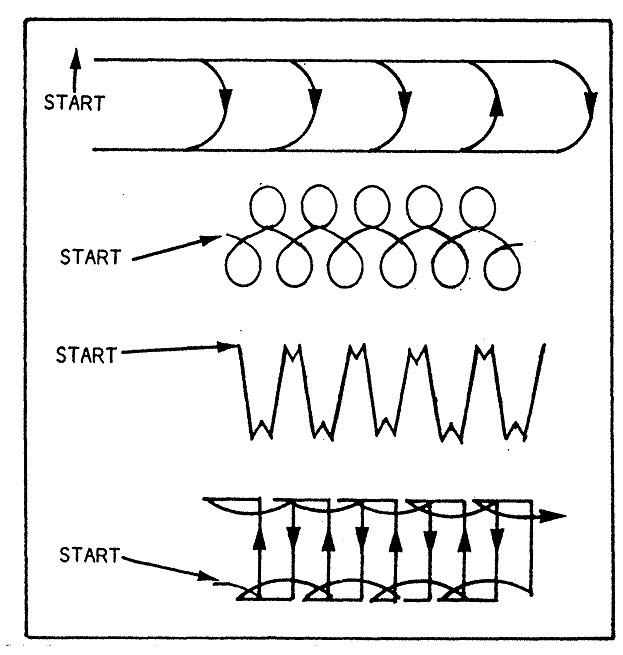

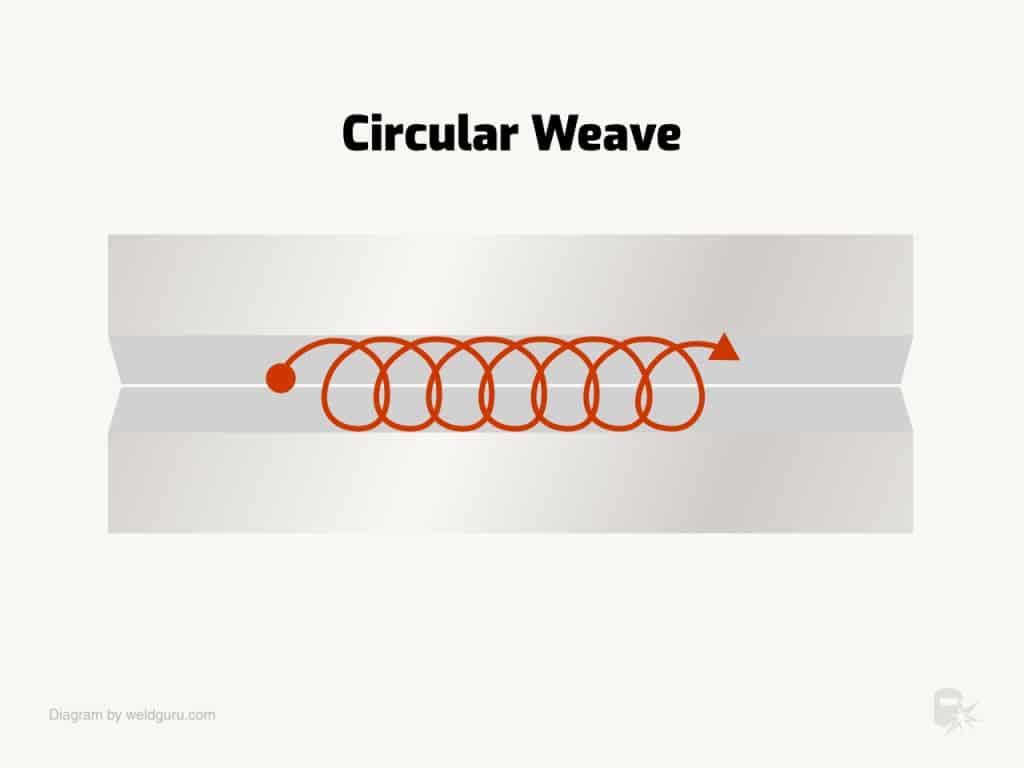

Mig Welding Weave Patterns - Learning different bead types will help you figure out what is beneficial for your specific projects and needs. Smoothtool offers four main patterns to choose from: There have been alot of posts and articles in off road magazines about how a weld should look and what causes problems. All patterns have pros and cons, difficulty levels, and the best situations to use them. Web this article will cover the types of welding beads that are common with the three main processes ( tig, stick, mig ). It’s quick to learn, and the equipment isn’t overly expensive. Tig welding uses filler rods instead of welding wire to form weld beads, but it’s known for creating very visually appealing welds as a result. The amount of curling is up to your personal preferences. Weaving while mig welding is comprised of swirling your hand with the welder. It doesn’t come without difficulties, though, as it’s a new skill you’ll be trying to master. These patterns give you reliable results based on specific requirements and welding projects. Crescent, circles, zigzag and trapezoid. These patterns significantly impact the final weld bead's shape, size, and penetration depth. It doesn’t come without difficulties, though, as it’s a new skill you’ll be trying to master. Web the weave pattern, circles pattern, and zigzag pattern are common mig welding techniques that offer unique benefits for various welding applications. Learning different bead types will help you figure out what is beneficial for your specific projects and needs. Web one important aspect of mig welding is the use of weave patterns, which refers to the motion of the welding torch during the welding process. Tig welding uses filler rods instead of welding wire to form weld beads, but it’s known for creating very visually appealing welds as a result. Web users can access a variety of weaving patterns through the weld node’s parameters tab. Web mig welding, also called gas metal arc welding (gmaw), is an awesome welding process for beginners to begin their welding journey. The example above is for multipass. Web users can access a variety of weaving patterns through the weld node’s parameters tab. These patterns help control weld width, penetration, reinforcement, appearance, and distortion. There have been alot of posts and articles in off road magazines about how a weld should look and what causes problems. Web the weave pattern, circles pattern,. These patterns give you reliable results based on specific requirements and welding projects. Weaves are good for big joints that have no distortion issues. Depending on the material being welded, its thickness, and its position, a certain weaving pattern will be employed. If i'm welding horizontal a d pattern seems work work pretty good. Crescent, circles, zigzag and trapezoid. There have been alot of posts and articles in off road magazines about how a weld should look and what causes problems. It’s quick to learn, and the equipment isn’t overly expensive. The amount of curling is up to your personal preferences. Like the welds on chaos or esb kits. Web should you weave when mig welding? Weaves are used for wider welds and range from a tight side to side motion that can be a stringer bead to welds that are wide and big for a single pass. / stick (smaw) / by jeff powell. It’s quick to learn, and the equipment isn’t overly expensive. Web what are weave patterns in mig welding? Just as a. Weave patterns distribute heat more evenly across the weld joint, reducing the risk of warping and distortion, especially in thin materials. It’s quick to learn, and the equipment isn’t overly expensive. It doesn’t come without difficulties, though, as it’s a new skill you’ll be trying to master. Web users can access a variety of weaving patterns through the weld node’s. Depending on the material being welded, its thickness, and its position, a certain weaving pattern will be employed. Crescent, circles, zigzag and trapezoid. If i'm welding horizontal a d pattern seems work work pretty good. Are you a beginner welder looking to explore the world of welding but feeling intimidated by the prospect of learning and mastering sticking patterns in. Web mig welding, also called gas metal arc welding (gmaw), is an awesome welding process for beginners to begin their welding journey. Web mig welding, one of the most straightforward processes to learn and master, can help new welders get a grasp on many basic weaving patterns to help them practice. But, just like with hardwire welding, when you vertically. Web weave patterns offer several advantages in mig welding and find extensive applications in various welding scenarios: It doesn’t come without difficulties, though, as it’s a new skill you’ll be trying to master. If i'm welding horizontal a d pattern seems work work pretty good. Each pattern describes a specific movement or shape that the welder’s hand makes during the. Weaves are used for wider welds and range from a tight side to side motion that can be a stringer bead to welds that are wide and big for a single pass. Weave patterns distribute heat more evenly across the weld joint, reducing the risk of warping and distortion, especially in thin materials. I searched but didn't come up with. Web selecting the correct pattern, such as weave or stringer patterns, can significantly impact the strength and solidity of the weld. This way, you avoid drips that can occur once the puddle gets too hot. Web most of the time, welders use stringer beads to create a solid weld, which is pretty common to mig. Web one important aspect of. These patterns significantly impact the final weld bead's shape, size, and penetration depth. Web what are weave patterns in mig welding? Whip motion (stick) walking the cup (tig) stringer beads. Web the six common mig welding patterns we’ll cover are the stringer, circle pattern, weaving pattern, whipping pattern, figure 8, and j pattern. Depending on the material being welded, its thickness, and its position, a certain weaving pattern will be employed. Web should you weave when mig welding? Web one important aspect of mig welding is the use of weave patterns, which refers to the motion of the welding torch during the welding process. Just as a note in most shipyards weaving is not allowed. Web most of the time, welders use stringer beads to create a solid weld, which is pretty common to mig. This way, you avoid drips that can occur once the puddle gets too hot. Here are the popular types of weaving patterns: Web this article will cover the types of welding beads that are common with the three main processes ( tig, stick, mig ). So my question is, how do you get a mig weld to look like a stack of dimes? Like the welds on chaos or esb kits. Web mig welding, also called gas metal arc welding (gmaw), is an awesome welding process for beginners to begin their welding journey. The amount of curling is up to your personal preferences.MIG Welding Weave Patterns Super Helpful Guide & Review

MIG Welding Weave Patterns Super Helpful Guide & Review

MIG Welding Weave Patterns Super Helpful Guide & Review

6 Essential MIG Welding Patterns To Master

MIG Welding Weave Patterns Super Helpful Guide & Review

24+ Mig Welding Weave Patterns PaldenEmaad

6 Essential MIG Welding Patterns To Master

Weaving in welding A comprehensive guide to weave patterns

6 Essential MIG Welding Patterns To Master

MIG Welding Weave Patterns Super Helpful Guide & Review

Web Weave Welding Is Achieved By Offsetting The Motion Of The Weld Arc As It Moves Along The Weld Path, Making It Ideal For Filling Wide, Flat Joints Or Welding Thick Metals.

Web Selecting The Correct Pattern, Such As Weave Or Stringer Patterns, Can Significantly Impact The Strength And Solidity Of The Weld.

I Searched But Didn't Come Up With What I Was Looking For.

If I'm Welding Horizontal A D Pattern Seems Work Work Pretty Good.

Related Post: